SHAPE

COLOR

CARAT

CLARITY

CUT

Diamond weight is expressed in carats. 1.00 carat equals 200 milligrams. Diamonds under 1.00 carat are expressed in ‘points.’ That means a 0.90 carat diamond is said to weigh “90 points.” You should know that two diamonds which weigh the same don’t always look the same size. To see examples, click above and “Learn With Videos.” You may also consult your jewelry professional, or contact us directly at igi.org.

A diamond’s color is caused by chemicals in the earth where the diamond formed. The most common color is yellow, and most diamonds are graded on a scale ranging from D, which is most colorless, to Z, which is light yellow or brown. To see examples, click above and “Learn With Videos.” You may also consult your jewelry professional, or contact us directly at igi.org.

Clarity evaluates a gemstone’s internal and external clarity-characteristics. Internal characteristics are classified as inclusions. External characteristics are classified as blemishes. A gemologist analyzes clarity by looking down through the top of the stone at 10-power magnification. To see examples, click above and “Learn With Videos.” You may also consult your jewelry professional, or contact us directly at igi.org.

The cut of a diamond refers to everything man has done to convert it from a rough diamond crystal into a finished gemstone capable of producing brightness, fire and scintillation. More than any other “C” the way a diamond is cut determines how big, bright and lively it appears. To see examples, click above and “Learn With Videos.” You may also consult your jewelry professional, or contact us directly at igi.org.

Lab-Grown Diamonds are identical to natural diamonds, with the same hardness, refractive index, and sparkle. They are graded using the same 4Cs. The only difference is they are not billions of years old. They are grown in factories using one of two sophisticated methods. To see examples, click above and "Learn With Videos." You may also consult your jewelry professional, or contact us directly at igi.org.

Have confidence in your diamond, gem and jewelry purchases with IGI. For more information consult your jewelry professional or contact us directly at igi.org.

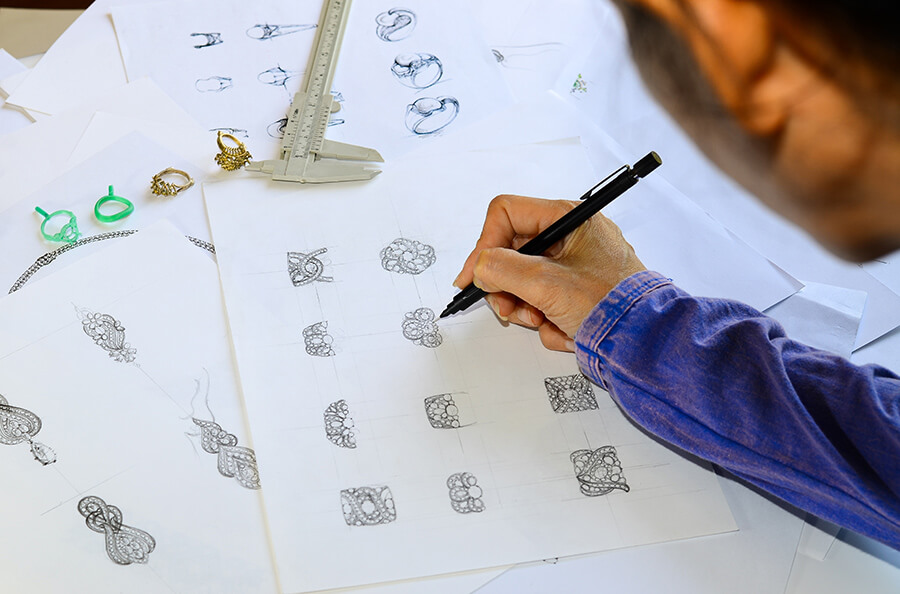

Your jewelry was conceived and fashioned by dedicated professionals from start to finish.

- Conception: A design was drawn using hand-sketches or CAD software

- Creation: A hardened mold was produced to accomodate your jewelry’s forging

- Casting: The molten precious-metal alloy was delivered into that mold under consistent pressure, promoting bonding, density and strength

Your jewelry was carefully removed, refined and cleaned, undergoing a rigorous dual-process of fine-tuning and polish prior to setting, whereafter it was thoroughly inspected for durability and quality, as well as beauty.

The process of jewelry-making

From artistic collaboration and direction to forging and cooling to detailed clean-casting and pre-polish. From secure, precision stonesetting to hours of final polish, every step was deliberate and meticulous.

Conception

Your piece was designed by visionaries. It may have been an artist using hand-sketches or a gemology graduate using modern CAD software. Professional jewelry designers must command both the basics and complexities of jewelry creation to perfectly balance the primary components of aesthetics, durability and cost.

Creation

An exact replica of your jewelry’s mounting was created in modeling wax. Whether hand-carved or rendered with high-precision 3D printers, that replica was refined to become a twin of your precious item. That twin was placed into a casting flask and encased in jewelry-quality investment. The investment hardened to form a perfect negative-replica mold, suitable for casting. Its job finished, the wax was superheated and removed with vacuum technology.

Casting

Your mold was taken to the foundry and your precious metal was brought to its melting point in a crucible. The metal alloy was delivered to the mold in a casting centrifuge with high-pressure inert gas, forcing your alloy into sub surface voids and facilitating diffusional bonding to promote density, strength and durability.

Cleaning

When finished and cooled your jewelry was carefully removed from the mold. It underwent the rigorous dual-process of clean-casting, where excess material was removed, and pre-polish, where the piece was thoroughly inspected and verified for fundamental quality and integrity.

Culmination

Stone-setting and polishing brought your finished jewelry to life. The setter meticulously balanced, seated and secured your gemstones, and the polisher brought all details of finish to culmination.

From conception to creation, a talented array of professional specialists took deliberate and meticulous steps in the careful forging of your jewelry.

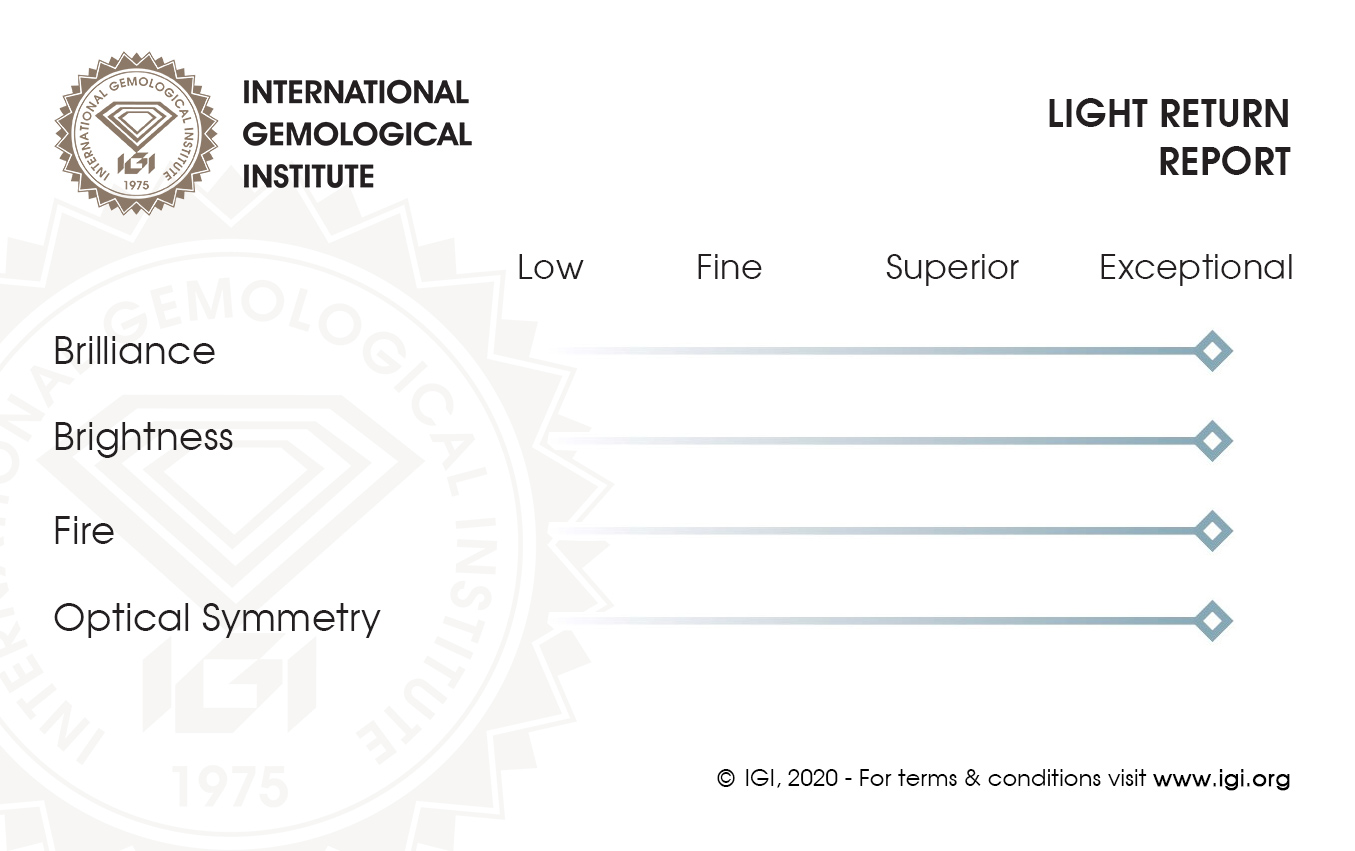

Light Performance Result

Brilliance

Brightness

Fire

OPTICAL SYMMETRY

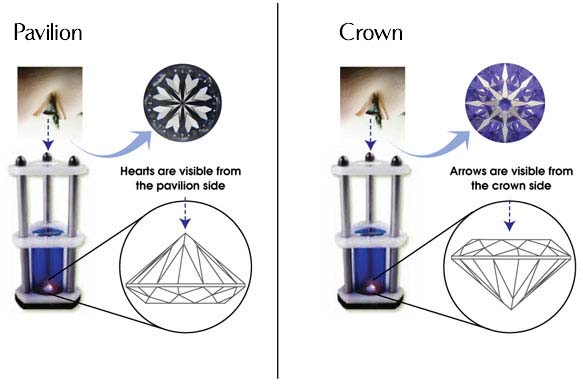

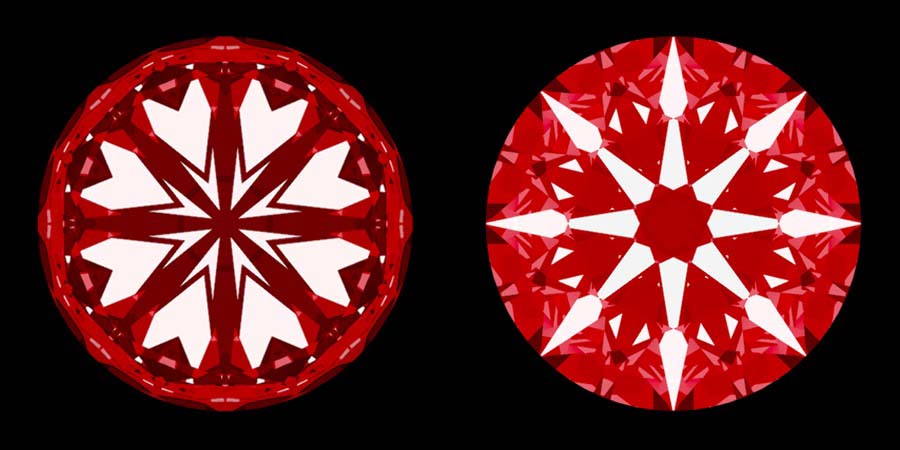

Hearts & Arrows Diamonds

"Hearts & Arrows" (H&A ) diamonds are cut so precisely that their facet reflections overlap when viewed in a reflective scope. Light from above becomes white whereas light from the sides becomes colored by filament paper. This creates a structured light environment where primary facet reflections appear white against a darker background, permitting analysis.

The kaleidoscopic pattern seen face-down in the pavilion resembles "Hearts," and the pattern seen face-up in the crown resembles "Arrows." Hearts & Arrows precision is associated with Excellent-Ideal cuts of superior quality.

Hearts & Arrows history

Japanese diamond cutters in the 1980s were first to produce round brilliant diamonds cut so exactly that their facet reflections overlapped in 3D space. Those polishers used “secret recipes” to create these so-called Hearts & Arrows patterns. Their techniques spread to other cutting houses and H&A diamonds began appearing on several continents by the mid-1990s.

Technical mastery

Diamonds are the hardest substance known to man, so producing strong H&A patterns requires more time in planning, higher labor skill and the best-quality cutting tools. The precision and crispness of the patterns relies on precise angles in combination with specific facet length, width and azimuth.

Diamonds held to the uppermost level of craftsmanship show extremely precise patterns. These exquisite diamonds are valued for the care, precision and consistency demonstrated in their cutting as much as any visible effects that results from this precision.

There is also the attractiveness of rarity. Just as D color and Flawless clarity are rare, so is the Hearts & Arrows (H&A) level of cut quality. Top H&A diamonds are valued for their uniqueness and quality as the ultimate in cutting precision.

Hearts & Arrows symbolism

The eight uniform patterns seen in the top and bottom of Hearts & Arrows (H&A) diamonds have a historical association with good fortune and spiritualism. The number eight is considered lucky in Asian culture. The arrows pattern has been compared to the octagram of the I Ching, the Rinbo of Buddhism and the eight-spoked wheel of Dharma, associated with spiritual perfection in the Buddhist faith.

Perfection in precision

Regardless of spiritual belief, the astonishing achievement of the perfect H&A pattern, painstakingly cut into the world's hardest substance, can be seen by any admirer of structure.

In its most fundamental form it symbolizes the diamond cutter's quest for perfection in precision and ultimate beauty in a diamond.

Your Diamond's Story

Your diamond was forged between one and three billion years ago deep beneath the earth’s surface. A powerful process called subduction, where ancient land masses moved against each another, produced enough pressure, friction and heat that fragments of carbon crystallized and grew into our planet’s supply of natural diamonds.

Volcanic delivery

Your diamond began its extraordinary journey toward your hands with a volcanic ride to the surface. Some diamonds lodged in the volcano’s throat. Others were blown clear and distributed over a large area by rivers of magma. Rain, erosion, ice-ages and other forces of nature, sustained for millions of years, buried some diamonds and released others from their mother rock - transporting them hundreds of kilometers away.

Diamonds have been discovered on nearly every continent. The most abundant gem-quality deposits are mined in Africa, Russia, Austalia and Canada.

A history beyond conception

Every natural diamond crystal has a history beyond conception and a forever-story larger than life. Billions of years old, your diamond existed before the dawn of man. Before tribes, clans and nations. Every diamond underwent a staggering growth process and made an extraordinary journey over countless ages before its discovery. Once recovered and sorted, your rough diamond crystal was sent for planning and cutting.

Rough to polish

Diamond cutting is the art, skill and science of transforming a raw crystal into a polished, faceted diamond. As the hardest material known to man, cutting and shaping a diamond requires specialized knowledge, tools and skill.

1) Planning: This rough octahedron crystal is studied and its growth directions and inclusions are mapped.

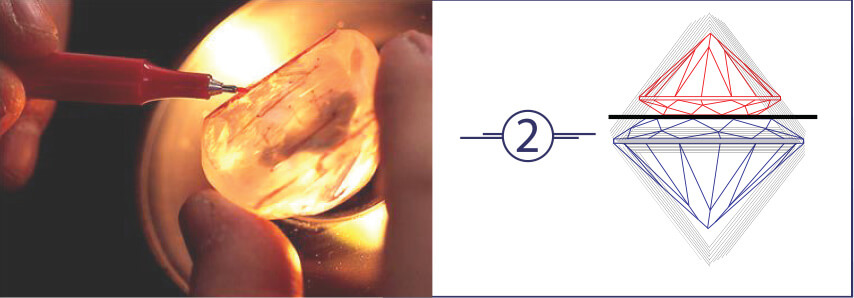

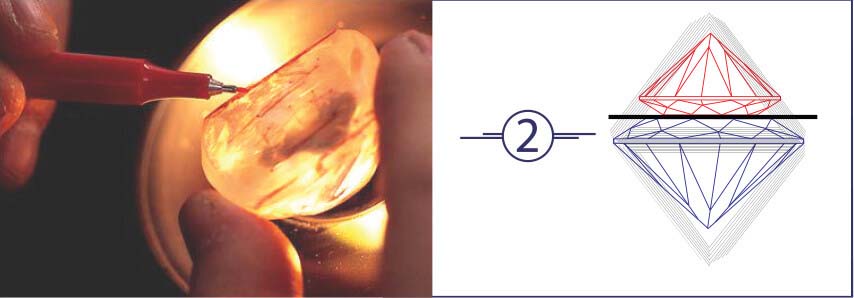

2) Marking: Once the plan is determined, the crystal is marked for primary sawing.

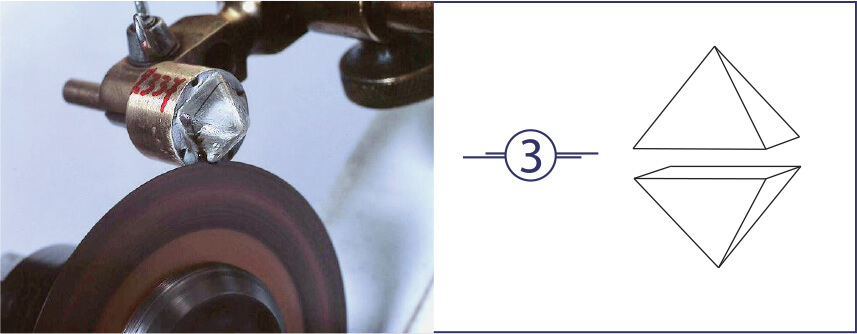

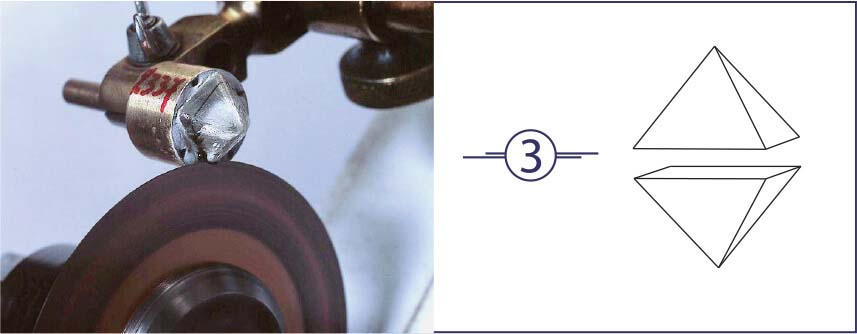

3) Sawing: A carbon-fiber blade coated with diamond-grit makes the first cut. It will take several hours to saw this crystal into two pieces; each of which will become a polished diamond.

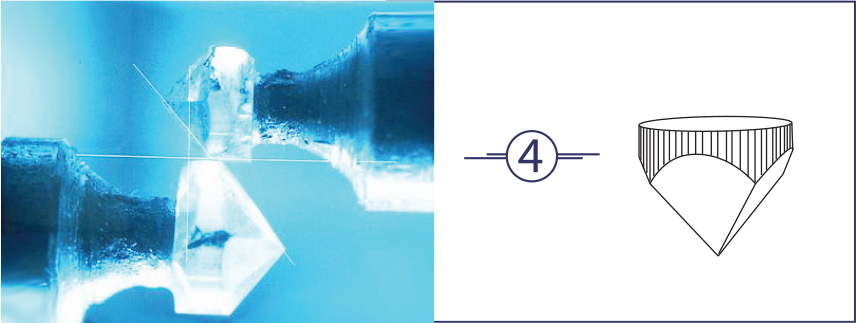

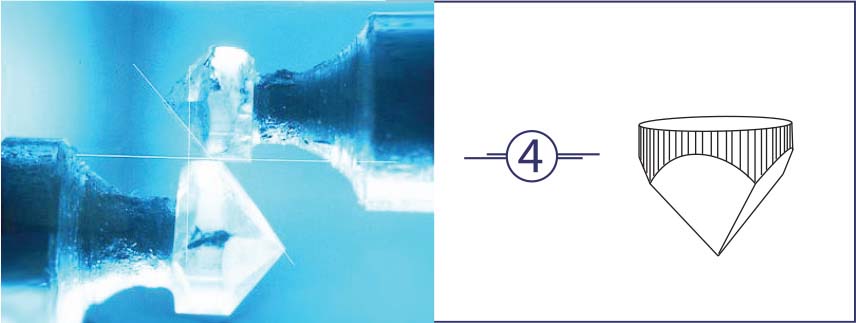

4) Bruting: The two pieces spin in opposite directions, grinding against each other to smooth the edges and create a round outline.

5) Polishing: A spinning wheel coated with diamond-grit is used for blocking, crossworking and brillianteering, the process of placing, shaping and smoothing all facets to final polish.

6) Inspection: Once finished, the diamond is thoroughly boiled in acid and examined to ensure that it meets the producer’s expectations and quality standards.

Diamond Grading

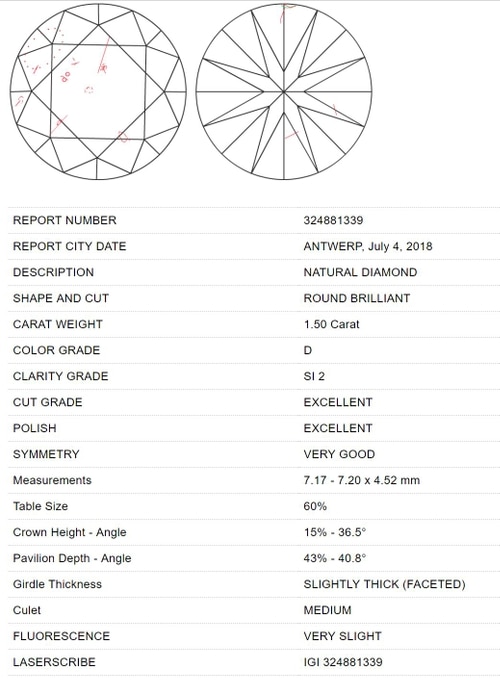

Following the diamond cutting process and prior to being sold loose or mounted into jewelry, diamonds are typically submitted to gemological institutions such as IGI for quality assessment. Four main factors are considered when judging a diamond’s quality and value. They are the diamond’s 4C’s: Carat weight, Color, Clarity and Cut.

IGI screens every diamond using state of the art technologies to determine naturally mined, laboratory grown or simulant origin. Experienced graduate gemologists conduct further assessment in controlled conditions, detailing relevant gemological characteristics according to the strictest international system.

Your diamond is exceptional and distinctive. No two diamonds are alike. Yet all diamonds have certain features in common that allow experts to compare and evaluate them.

Uniquely yours

The name diamond is derived from the ancient Greek “adamas” meaning unbreakable, untamed and unconquerable. Diamonds have been treasured as gemstones ever since they were discovered. In our modern age the word “diamond” continues to evoke images of elegance, style and glamour.

Diamond sparkles and dazzles. Diamond symbolizes purity and strength. And the story of your diamond is uniquely yours.

Your Diamond's Creation

Your laboratory-grown diamond is chemically identical to every other diamond on earth. However, instead of mined diamonds, which formed beneath the ground billions of years ago, your diamond was grown in controlled laboratory conditions using sophisticated methods of chemical synthesis.

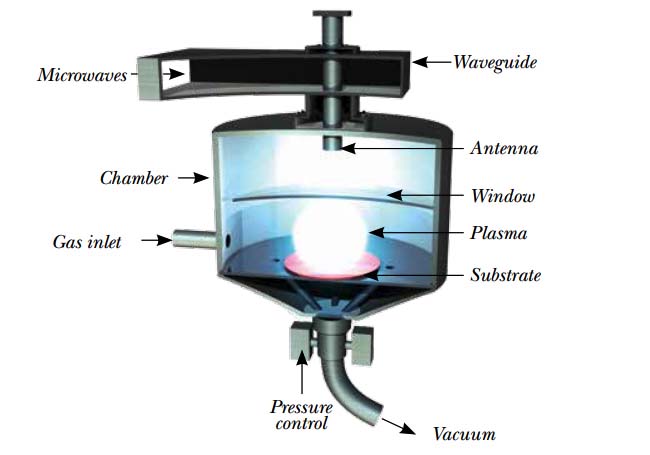

The most modern technology

There are two scientific approaches to diamond creation. The Chemical Vapor Deposition (CVD) process releases carbon from plasma. This involves superheating hydrocarbon gas in a vacuum to between 3,000-4,000C, at which point the carbon atoms begin to separate from their molecular bonds. Those atoms descend and land on a flat wafer of previously grown synthetic diamond and grow in vertical layers. This substrate is square for jewelry applications but the shape can vary for other applications in medicine, communications and technology.

The High Pressure High Temperature (HPHT) process replicates the natural conditions under which diamonds formed 100 miles below the surface due to subduction. A carbon source, a diamond seed and a metallic catalyst go into an octahedral cell. The cell is placed into a massive mechanical press where the contents are heated near 1,500 C and subjected to staggering pressure. The melting metal dissolves the carbon and the pressure causes precipitation to the diamond seed, growing a larger diamond. The level of pressure from these immense presses has been compared to what you’d experience if you balanced a jumbo jet on the tip of your finger.

When the growing process has finalized, rough CVD and HPHT crystals are sent to diamond cutting centers to be planned and polished.

Rough to polish

Diamond cutting is the art, skill and science of transforming a raw crystal into a polished, faceted diamond. As the hardest material known to man, cutting and shaping a diamond requires specialized knowledge, tools and skill.

1) Planning: This rough octahedron crystal is studied and its growth directions and inclusions are mapped.

2) Marking: Once the plan is determined, the crystal is marked for primary sawing.

3) Sawing: A carbon-fiber blade coated with diamond-grit makes the first cut. It will take several hours to saw this crystal into two pieces; each of which will become a polished diamond.

4) Bruting: The two pieces spin in opposite directions, grinding against each other to smooth the edges and create a round outline.

5) Polishing: A spinning wheel coated with diamond-grit is used for blocking, crossworking and brillianteering, the process of placing, shaping and smoothing all facets to final polish.

6) Inspection: Once finished, the diamond is thoroughly boiled in acid and examined to ensure that it meets the producer’s expectations and quality standards.

Diamond Grading

Following the diamond cutting process and prior to being sold loose or mounted into jewelry, diamonds are typically submitted to gemological institutions such as IGI for quality assessment. Four main factors are considered when judging a diamond’s quality and value. They are the diamond’s 4C’s: Carat weight, Color, Clarity and Cut.

IGI screens every diamond using state of the art technologies to determine naturally mined, laboratory grown or simulant origin. Experienced graduate gemologists conduct further assessment in controlled conditions, detailing relevant gemological characteristics according to the strictest international system.

Your diamond is exceptional and distinctive. No two diamonds are alike. Yet all diamonds have certain features in common that allow experts to compare and evaluate them.

Uniquely yours

The name diamond is derived from the ancient Greek “adamas” meaning unbreakable, untamed and unconquerable. Diamonds have been treasured as gemstones ever since they were discovered. In our modern age the word “diamond” continues to evoke images of elegance, style and glamour.

Diamond sparkles and dazzles. Diamond symbolizes purity and strength. And the story of your diamond is uniquely yours.

Forging your jewelry

Your jewelry was conceived and fashioned by specialists from start to finish. From artistic collaboration and direction to forging and cooling to detailed clean-casting and pre-polish. From secure, precision stonesetting to hours of final polish, every step was deliberate and meticulous.

Conception

Your piece was designed by visionaries. It may have been an artist using hand-sketches or a gemology graduate using modern CAD software. Professional jewelry designers must command both the basics and complexities of jewelry creation to perfectly balance the primary components of aesthetics, durability and cost.

Creation

An exact replica of your jewelry’s mounting was created in modeling wax. Whether hand-carved or rendered with high-precision 3D printers, that replica was refined to become a twin of your precious item. That twin was placed into a casting flask and encased in jewelry-quality investment. The investment hardened to form a perfect negative-replica mold, suitable for casting. Its job finished, the wax was superheated and removed with vacuum technology.

Casting

Your mold was taken to the foundry and your precious metal was brought to its melting point in a crucible. The metal alloy was delivered to the mold in a casting centrifuge with high-pressure inert gas, forcing your alloy into sub surface voids and facilitating diffusional bonding to promote density, strength and durability.

Cleaning

When finished and cooled your jewelry was carefully removed from the mold. It underwent the rigorous dual-process of clean-casting, where excess material was removed, and pre-polish, where the piece was thoroughly inspected and verified for fundamental quality and integrity.

Culmination

Stone-setting and polishing brought your finished jewelry to life. The setter meticulously balanced, seated and secured your gemstones, and the polisher brought all details of finish to culmination.

From conception to creation, a talented array of professional specialists took deliberate and meticulous steps in the careful forging of your jewelry.

360 View

REPORTS

REPORTS